What should be paid attention to when processing plasti […]

What should be paid attention to when processing plastic molds

1. Since molds are developing in the direction of large-scale, molds of several tons to tens of tons are very common, so the machine tool table is required to withstand large weight, which requires the equipment to have large load-bearing and high rigidity characteristics, and it must have enough The large table size and working stroke are compatible with it. The strength and hardness of the mold material are high. In addition, small diameter end mills with large elongation are often used to process the mold cavity, so chatter vibration is prone to occur during the processing. In order to ensure the machining accuracy and surface quality of the parts, the high-speed universal milling machine for mold manufacturing must have high dynamic and static stiffness to improve the positioning accuracy, tracking accuracy and vibration resistance of the machine tool.

2. High-speed and high-power high-speed machining is the development direction. High-speed milling has shown great advantages in mold processing. In order to adapt to the processing of the mold cavity surface, the radius of the tool should be smaller than the minimum circumferential radius of the cavity surface to avoid "interference" between the tool and the workpiece during the processing. Because the tool diameter is small, the spindle speed is required to be very high, and the spindle speed of foreign high-speed machining machine tools It has reached 40,000 ~ 100,000 r/min, and the rapid feed rate can reach 30,000 ~ 60,000 min. The roughing and finishing of cavity and other parts of mold parts are often completed in one clamping of the workpiece, so the spindle power must be large. The spindle power of medium-sized mold milling machines and machining centers is often 10-40kw, and some are even higher.

3. Multi-axis linkage and good deep cavity comprehensive cutting ability. Most mold cavities are composed of complicated space six curved surfaces and grooves, and many molds have deep cavities. In order to achieve high-precision, high-speed and high-stability machining of 3D surfaces, the machine tool needs multi-axis linkage and has a good comprehensive cutting ability for deep holes. A five-axis linkage machining center can be used. In addition to the linear motion of the three coordinates, there are also two feed motions of the rotating coordinates. The milling head or worktable can continuously rotate and feed in multi-axis linkage, which is suitable for processing mold parts with complex cavity surfaces. It can be said that compound processing is one of the development directions of mold processing.

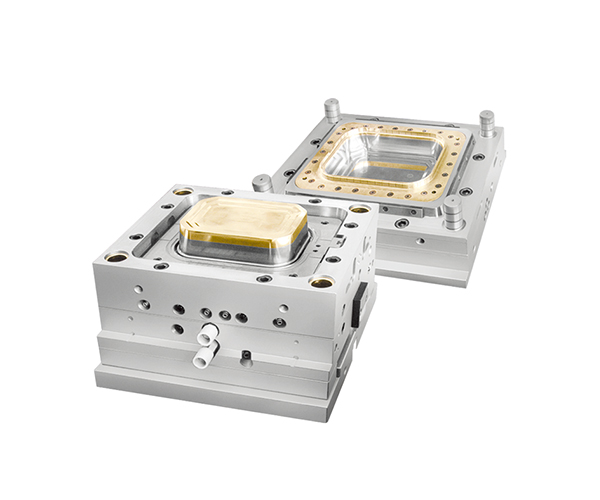

Taizhou Huangyan Yuantu Mould Co., Ltd. specialized in auto parts mold, home appliance mould, commodity mould and so on. We do both OEM parts and AM parts.

CLICK https://www.yuantumould.com/product/