In the correct use of plastic mold steel, it is also ne […]

In the correct use of plastic mold steel, it is also necessary to regularly protect and maintain the mold steel. The protective protection of the mold steel is planned, and the data processing in the protection process is carried out to prevent possible problems in the production of the mold steel, and the efficiency of the repair operation.

⑴ The planning of the parts should be reasonable, and the best structural plan should be selected as much as possible.

The planner of the part must consider that the technical requirements and structure of the part must meet the process and feasibility of mold steel manufacturing.

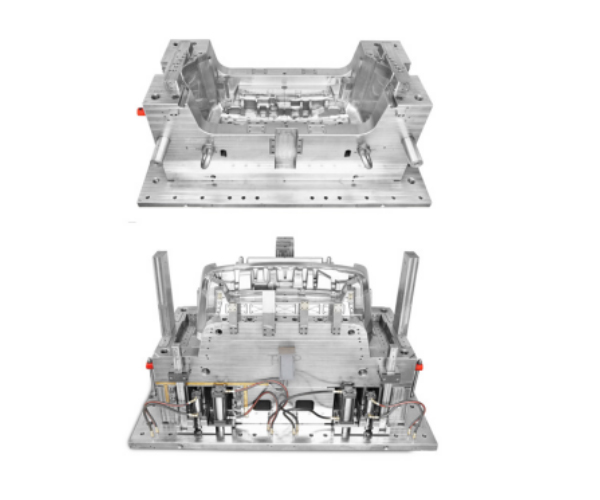

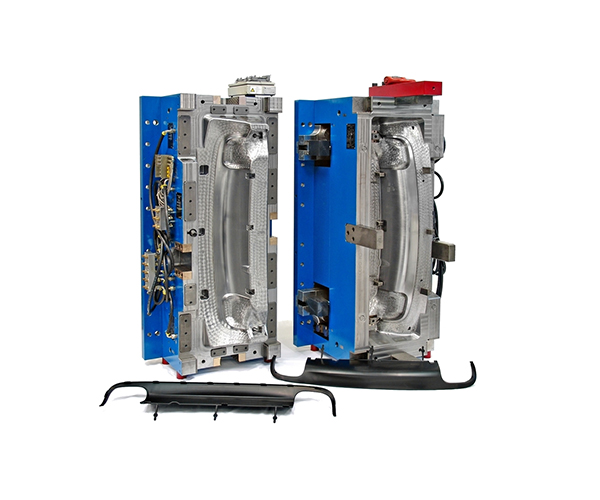

⑵ Mold steel planning

This is the most important step in the quality of mold steel. Many factors need to be considered, including the selection of mold steel materials, the availability and safety of mold steel structure, the workability of mold steel parts and the convenience of mold steel repair These should be considered as thorough as possible at the beginning of planning.

① The selection of mold steel materials should not only satisfy the customer's requirements for product quality, but also consider the cost of the materials and their strength within the set period. Of course, it must also be based on the type of mold steel, operating methods, processing speed, and primary Selection of materials by factors such as failure form.

② When planning the mold steel structure, try to be as compact as possible and easy to operate, and ensure that the mold steel parts have sufficient strength and rigidity; when the mold steel structure allows, the corners of the mold steel parts should be planned as rounded transitions as much as possible. In order to prevent stress convergence; for the concave mold, cavity and part of the punch and core, you can choose a combination or inlay structure to eliminate stress convergence. For the slender punch or core, appropriate protection methods must be selected in the structure; Cold punching dies should be equipped with equipment to prevent clogging of parts or waste materials (such as ejector pins, compressed air, etc.). At the same time, it is also necessary to consider how to reduce the impact on the quality of mold steel caused by the wear of sliding parts and repeated impact parts during long-term use. To

③ In the planning, it is necessary to reduce the disassembly and assembly planning when repairing a certain part, especially when the wearing parts are replaced.

⑶ Mold steel manufacturing process

This is also an important part of ensuring the quality of mold steel. The processing methods and machining accuracy in the mold steel manufacturing process will also affect the service life of the mold steel. The accuracy of each part directly affects the overall equipment of the mold steel. In addition to the accuracy of the equipment itself, it is necessary to improve the processing methods of the parts, and the technical level of the traveling fitter in the mold steel grinding and matching process to advance the mold steel parts. Processing accuracy; if the overall equipment of the mold steel fails to meet the requirements, the mold steel will be allowed to move in an abnormal state during the trial mold, which will have a great impact on the overall quality of the mold steel.

In order to ensure that the mold steel has excellent original precision—the quality of the original mold steel, the high-precision processing methods must be selected reasonably during the manufacturing process, such as electric discharge, wire cutting, CNC machining, etc., and attention should be paid to the accuracy of the mold steel. , Including the machining accuracy of mold steel parts, equipment accuracy, and the accuracy of the mold steel that has been summed up through the mold trial inspection operations. When checking, it is necessary to use high-precision measuring instruments as much as possible. Regarding the mold steel parts with a messy surface and surface structure, if It is impossible to reach accurate measurement data with ordinary rulers and vernier cards. At this time, precise measurement equipment such as a three-coordinate measuring instrument must be selected to ensure the accuracy of the measurement data.

⑷ Strengthen the appearance of the main forming parts of mold steel

In this way, the surface wear resistance of mold steel parts can be improved, and then the quality of mold steel can be improved.

Regarding the appearance strengthening, different strengthening methods should be selected according to the mold steel used for different purposes. In addition, a technology called FCVA vacuum diamond coating developed in recent years can form a very strong and very lubricating uniform and dense protective film on the surface of the part. This technology is particularly suitable for the surface of mold steel. Protective treatment is also a significant way to improve the quality of mold steel.

⑸ The correct use and protection of mold steel is also a major element of the quality of marching mold steel.

In recent years, the competition in the mold steel manufacturing industry within the world plan has become more and more fierce. The ability of enterprises to provide customers with personalized and high-quality products in the shortest possible time with high efficiency and low consumption has become the talent of enterprises. A sign.

https://www.yuantumould.com/product/auto-parts-mould/