In recent years, 3D printing technology has been like a […]

In recent years, 3D printing technology has been like a spring breeze, and it has been heated up (the standard name of this technology is "additive manufacturing"). Experts from all walks of life talk about the magical power of 3D printing products, and even predict the mold The industry is dead end". What do you think of 3D printing technology?

First of all, we must clearly distinguish our roles. As industry insiders, why should we listen to some nonsense bricks to brag about? They don't even know what the mold is, they just boast about seeing that 3D printing can produce a product.

The significance of industrial molds is to achieve high-volume and efficient production, and greatly reduce the production of finished products. 3D printing currently only solves the production of a small part of the sample, and its efficiency and cost are not a level compared with mold production.

For example, in the production of mineral water bottle caps, the demand for similar products is often on the order of tens of millions, and the final amortized cost of the products made with molds is only a few cents. If you change to 3D printing, you can try it. You don’t even have enough electricity bills, not to mention labor and consumables, and the efficiency is also a thousand miles away... You can make an analogy, the mold is the printing factory, and the 3D printing is you. The office printer, a magazine with a circulation of 100,000 copies, would you use a printer to print it?

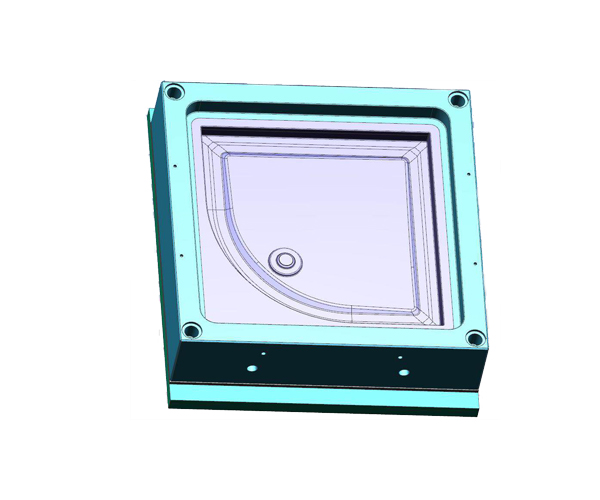

https://www.yuantumould.com/product/home-appliance-mould/

On the contrary, 3D printing has brought innovation and vitality to the mold manufacturing industry. Since trial products can be obtained and confirmed in advance through 3D printing, repeated mold changes and even mold project failures after mold opening are reduced. There is also the emergence of metal 3D printing technology, which can manufacture molds with conformal cooling channels, which improves mold production efficiency and product quality.

There is some publicity that 3D printing can directly print molds. That is just to show you the principle of presenting molds. It should be said that it is a "model". You can use this model to make some products, but can it be mass-produced? Is production stable? Not to mention the plastic model, even if it is a metal mold, can the hardness of your mold meet the requirements? Molds are not a joke. Domestic mold steels can't meet the performance requirements. Because of the pursuit of mold life and performance, the current model should not be complacent.

In fact, 3D printing technology has been out for many years, and I don’t know why it has been so hot recently! 3D printing is a very promising technology. We have to look at it correctly. There is no need to reject it, but we should not be confused by some false images.